125A Custom Distro with 4 x 63A and then some…

The Brief…

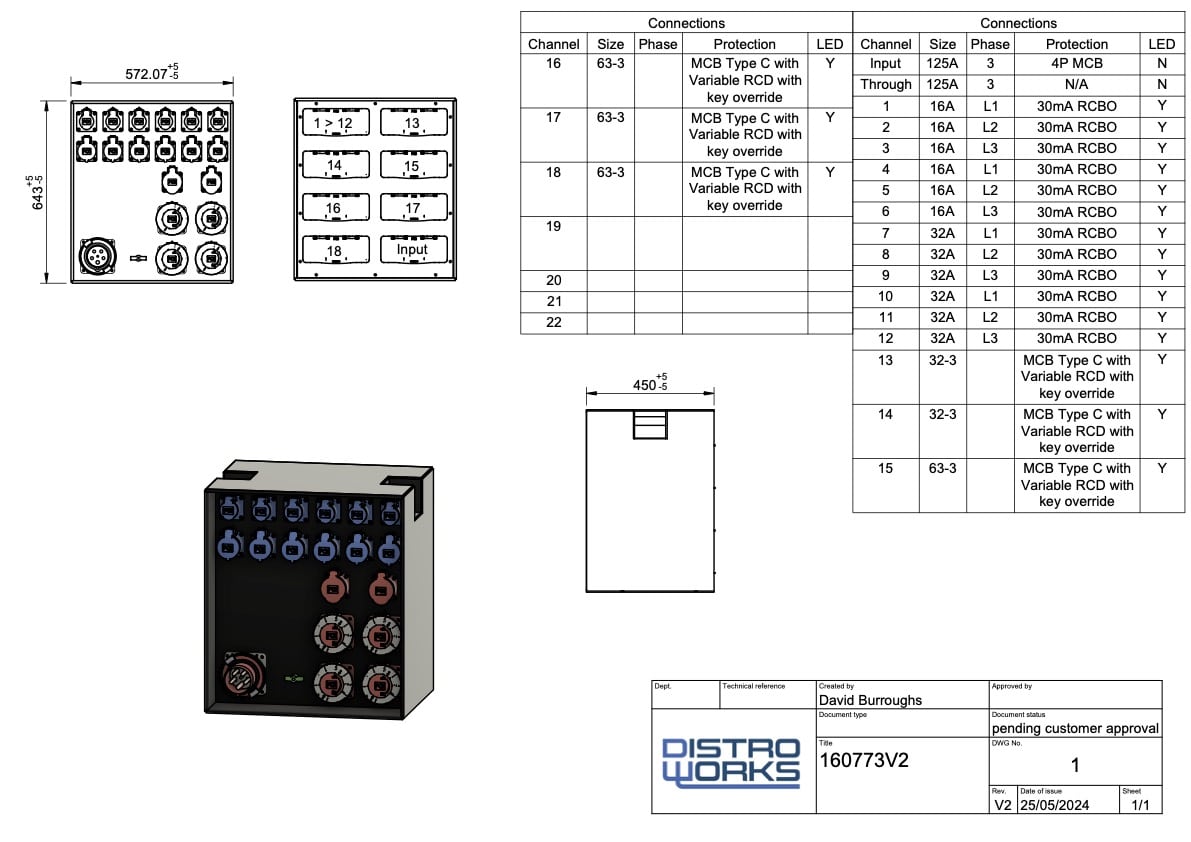

A new customer in the events industry contacted us to discuss their requirements for a 125A custom distro. They really liked the look of our distros but they wanted specific outputs. These included 4 x 63A and 2 x 32A Three Phase with Variable RCD protection. We priced up their specification with variable RCDs on all of the three phase outputs and sent the quote over. Following a couple of slight modifications to the original list of outputs the customer was happy with their quotation and placed the order.

The Design…

Once the order was placed, our drawing team set to work to put the specification list into the CAD software. They generated a visual of how the distribution board will look. We based this on our 125A Stock Distro which was designed for the temporary events industry. This was our core design for the outputs layout. Modifications were made to the window panel to make room for an extra row of circuit protection. Our 125A Stock Distro is currently equipped with just three variable RCD outputs. This temporary distribution board required 6 variable RCDs. Our drawing was sent to the customer for approval. Within a couple of hours, the response “That looks really good” was received and we could finalise our drawings ready to manufacture the 125A custom distro.

The Build…

When the 125A custom distro design is sent to manufacturing, it is first loaded onto the CNC machine to precision cut each part. These are then welded together by our fabrication team who will have a finished enclosure put together in a few hours.

The box is then passed to our wiring team. They install all of the electrical components such as PCE Connectors and connect them together. Each temporary distribution board design is different and every custom distro gets carefully designed. This ensures that all of the sockets and circuit protection will fit. We also have to consider the internal cable distribution and what components we will use inside.

Following on from the wiring, a different Engineer will look over the distro and perform spot checks on terminal tightness and a visual inspection. This will then be tested inline with our procedure including insulation resistance, polarity and RCD tests. We add channel stickers to show the three phases and a manufactures label. Before shipping the finished temporary event distro we give it a final clean.